Type | Item | Parameter |

Facility Requirement

& Appearance | Power Input | 220V 50/60Hz |

| Pneumatic System | Compressed air flow >2LPM; System supply pressure 0.6MPa-0.7MPa |

| Vacuum System | Vacuum gauge reading ≤ -80kPa |

| Environmental Conditions | Temperature: 15-35°C; Humidity: standard 70% at 32°C; Cleanliness level: 100k Class |

| Machine Dimensions | 1200mm×1000mm×2000mm |

| Equipment Weight | 1100-1250kg |

| Safety Protection | Product Safety Protection | Contact grounding treatment |

| ESD Protection | Ion fan for electrostatic removal |

| Software Protection | Mistake proofing |

| Equipment Protection | Collision prevention, axis stroke limit, distance sensor |

| Operator Safety Protection | Protective goggles |

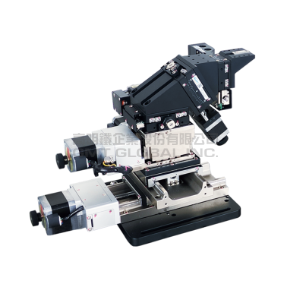

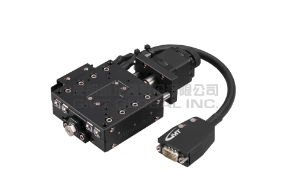

| Alignment Module | Operating module | Dual 6-axis System |

| Workpiece Clamping | Electric clamp, vacuum suction fixation |

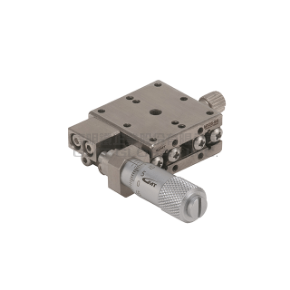

Single-Axis Repeatability

XYZ Drive Mechanism | ±0.05μm

Step motor with ball screw |

| θx | Manual adjustment |

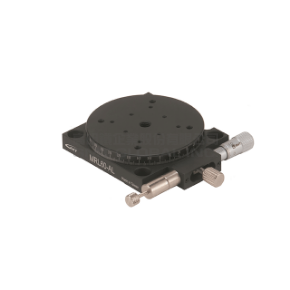

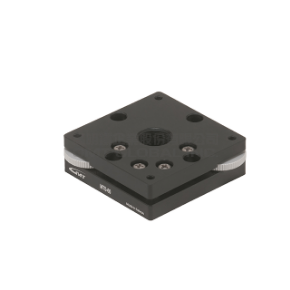

High-Precision Alignment Stage

θy/θz | Automatic stage Repeatability: ±0.001° |

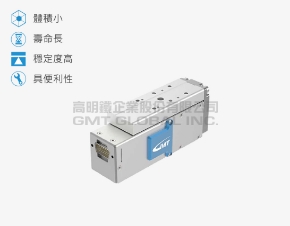

| Dispensing Module | Structural Configuration | Pneumatic extension dispensing supply (XY manual stage position fixation) |

| Dispensing Method | Bottom-side dispensing |

| Dispensing system | Dual dispensers; Musashi high-precision single-Point dispenser (needle type),

Standard 3mL capacity, other volumes customizable |

| Device Biasing Method | Socket connection | Automatic alignment |

Loading/

Unloading Module | Lens loading tray | 32pc dual lens tray |

| PCB | Single PCB tray with Pneumatic clamping |

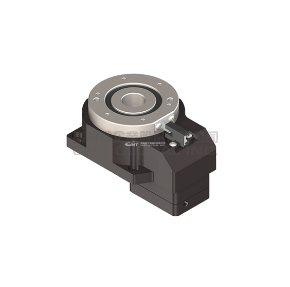

| UV Curing System | UV type | HOYA LED light source×4set; Wavelength 365nm |

| Operate axis | 6-axis, integrated in the left coupling axis |

| Visual system | Number of Camera | 2 |

| Visual recognize | Automatic alignment;5 Megapixel CCD;Visual range 5.6×4.7mm;Resolution:1.4 um;Depth 0.3mm |

| Camera axis | XYZ 3 axis: step motor with ball screws |

| Alignment System | Alignment stability

(Average Variance value) | <±5% |

| Level adjustment | Automatic alignment module |

| High adjustment | Pressure sensing |

| CT | < 200 sec/channel (Not including curing time, Depending on application scenario) |

| Software | Programming language | LabVIEW |

| Data binding | Capable to record production orders, product codes |

| Storage | Production data can be saved |

| Program calls | Program base can save multiple alignment programs to fit different alignment process |

| Power Meter | Type | Keithley E3646A (Can be modified according to requirements) |

| Voltage/Current range | Keysight (0-8V,3A/0-20V,1.5A) |

| Measure resolution | Voltage: <0.05% +5mV / Electric current <.15% + 5mA |

-01_4.jpeg)